Navigate

Our Solutions

- Transformer fleet health assessment

- Transformer failure and ageing due to moisture

- Sulphur corrosion in transformers

- Generator and auxiliary health assessment

- Process downtime due to power supply dip and sag

- Switching surge risk assessment

- Power factor correction solutions

Our Products

About Us

Welcome to the IGS Engineering services Company's website.

IGS's Solutions - Transformer health and integrity assessment programme

The integrity and health of power transformers on an industrial plant, plays a major role in the reliable and safe operation of an industrial or power plant. As a single failure can lead to prolonged production downtime our customers are keen to understand the integrity and health of their equipment. IGS also provides solutions and advice on what measures that could be implemented to extend useful life, reliability and integrity.

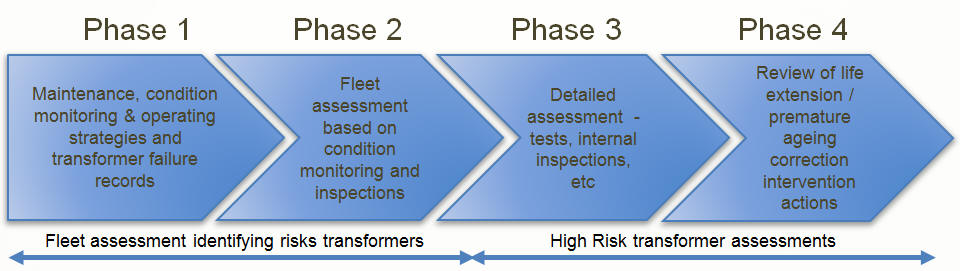

Transformers can work for many years provided they are correctly designed, applied and maintained. The IGS programme is all about assessing how the transformer is applied, used and maintained. Further monitoring indicators, test, and inspection results are also used in the assessment. The IGS programme is based on the international standard PAS 55-2 standard and its proven principles and is carried out in their recommended phases as shown below. Customers can buy into any one, combination or all of the phases.

During the first phase, experts with many years of experience in large transformer fleet management reviews the maintenance, condition monitoring, and operating strategies of the company and recommendation on these are made.

During the second phase the experts uses internationally developed software to review the condition of each transformer. Plant walk-down inspection and non intrusive testing is carried out using standard computerised check sheets generating automated scores. This internal software system enables IGS to carry out the inspections quickly and efficiently. The information is then used to rank the risk of the fleet and high risk transformers are then identified. The risk not only considers the technical indicators but the importance of the transformers to your business and production needs.

Transformers imposing a high risk to your business is then identified and take further into phases 3 to 4. In phase three, detailed assessment, testing and inspections are carried out on the high risk transformers, the nature of which depends on the cause of the risk. Countermeasures, interventions, and / or life extension measures are identified and the best economical solution and lifecycle cost studies are carried out, finding the best and cost effective intervention. The last phase is to observe and verify the effectiveness of the intervention when the cycle can be restarted at Phase 2 after a some time delay.

The benefit of using IGS services and plans are:

-

Use a leading well established international database and technology.

-

Based on all international best standards and best practices.

-

Experienced Specialist & Expert engineer assessment of transformer health.

-

Standard indexes and ratings allowing benchmarking.

-

Team approach with different levels of engineers – cost savings.

-

All results kept in data bases and server for future records. All available to insurance.

-

Re-assessments later will be at a cost savings as records will be maintain

-

Efficient assessment methods of standard sheets and using computer, technologies.

Asset management is all about knowing the integrity of your plant and optimizing capital expenditure keeping the risk of plant failure, production downtime and safety to a minimum. The IGS program help you to optimize you asset management processes and offers the following advantages:

-

Alleviate transformer failures and fire.

-

Know and manage risks.

-

Optimum capital expenditure.

-

Optimum plant life span that fits your business needs.

-

Reduce costly downtime and surprises.