Navigate

Our Solutions

- Transformer fleet health assessment

- Transformer failure and ageing due to moisture

- Sulphur corrosion in transformers

- Generator and auxiliary health assessment

- Process downtime due to power supply dip and sag

- Switching surge risk assessment

- Power factor correction solutions

Our Products

About Us

Solutions to Voltage Dip Process Interruption

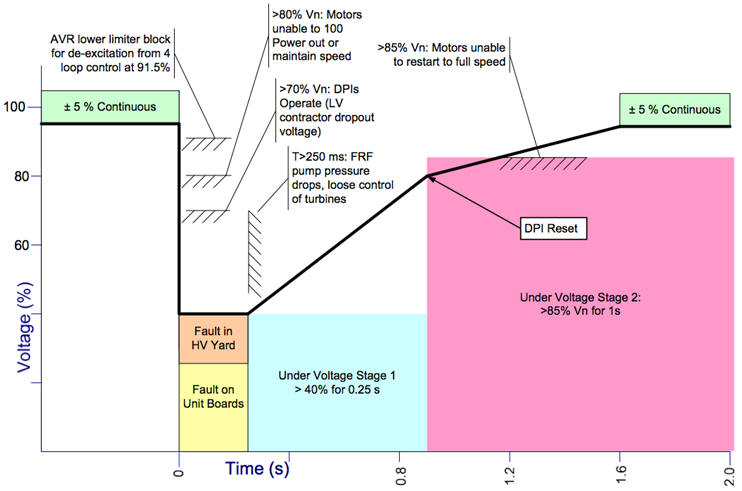

Momentary dips or sags in supply voltage to industrial or power plant auxiliary systems, are often the cause of process interruption or downtime. These dips are caused by lightning strikes on lines, short circuits or faults on the supply or auxiliary system. Voltage sagging is caused by switching of heavy loads such as starting of large motors and bulk load.

Dips or sags will effect electrical some

tripping immediately and others such as motors will loose torque and

drop in speed.

Motor and other control systems will normally shutdown very quickly stopping drives essential for the continuous running of the plant. Our expert engineers have many years of experience and have implemented voltage dip proofing solutions on several plants in the past.

Our Solutions

IGS quality plans and procedures are

based on world best practices and results. The process is shown in

the figure on the right hand side. Past events are carefully

studied and problem areas are identified. A voltage dip and sag strategy is then defined and tested against the plant

capabilities. An example of such an strategy compiled by our

experts is shown below. Potential modifications are then

identified and their impact is assessed. Economic

assessments are done finding the mitigation plan with the best economic

value.

dip and sag strategy is then defined and tested against the plant

capabilities. An example of such an strategy compiled by our

experts is shown below. Potential modifications are then

identified and their impact is assessed. Economic

assessments are done finding the mitigation plan with the best economic

value.

IGS uses the latest technology and methods that have been proven in practice. One such solution is the DPI or Dip Proofing Inverter. Read more about this unique product by clicking here.

Read more about power quality problems and comparison of DPI with UPS and other methods.